- Home

- Air Intakes

- Eventuri Mini Cooper S (F56) Plastic Intake + Carbon Scoop

Sold out.

Description:

As of 4/1/2021 Current Lead Time 12weeks!

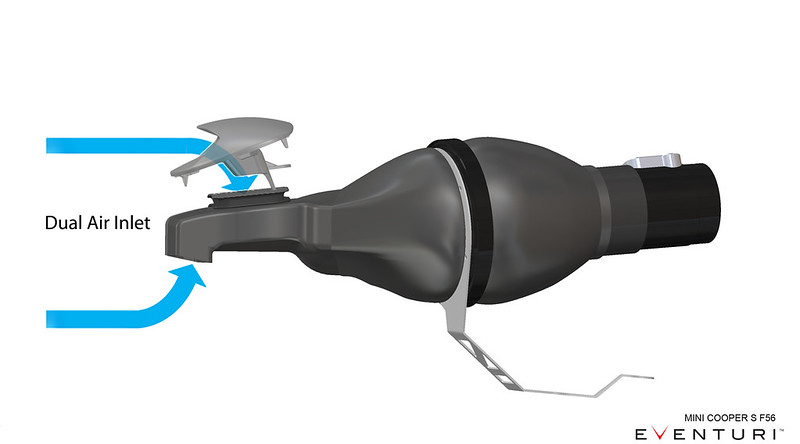

The F56 MINI Eventuri intake system is another example of our “Complete System” principal. It is a sealed system which ensures that the turbo does not draw hot air from the engine bay but enhanced with a functional bonnet scoop which forces ambient air into the intake duct. This duct has a larger internal volume than the stock version and also draws air from the stock location above the radiator. The combination of a sealed system with an air scoop results in lower intake temperatures than the stock airbox and avoids heat soak which is a common issue especially on higher powered MINIs. To ensure the smoothest flow possible we use our Patented filter housing coupled with a CNC machined MAF tube to ensure the smoothest possible flow to the turbo.

The Eventuri Difference

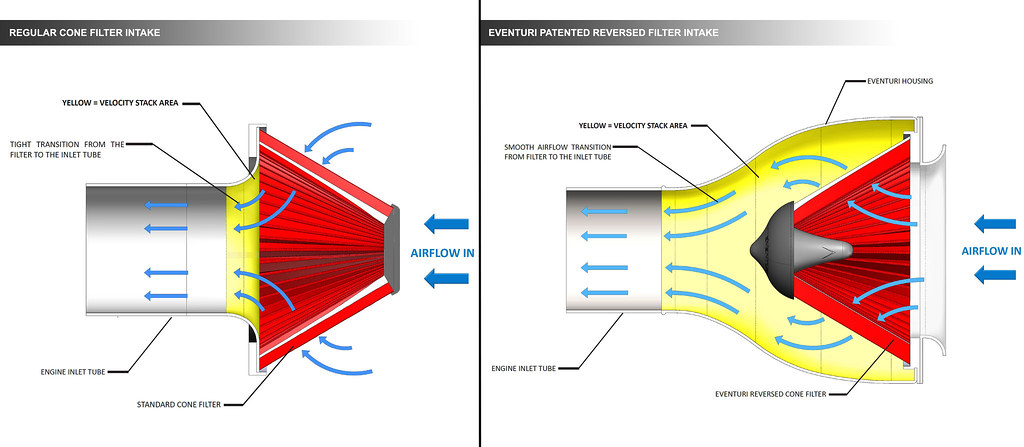

The F56 MINI Eventuri system uses our Patented Housing which provides an aerodynamically efficient airflow path from the filter to the turbo. Not just another cone filter with a heat shield but a unique design which invokes the Venturi affect and maintains laminar flow conditions to reduce the drag on the turbo.

* The JCW tested had a stage 2 map and downpipe. Performance gains measured with these modifications fitted for both stock airbox and Eventuri.

The Eventuri F5X Mini Cooper intake system consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. Here are the details for each component and the design ethos behind them:

Each intake system consists of:

- Plastic Venturi Filter Housing (Also Available in CArbon)

- Bespoke High Flow Non-Woven Mesh, Dry Cone Filter

- Plastic inlet Duct

- Carbon Fibre Inlet Scoop

- CNC Machined and insulated MAF Tube

- Laser Cut Stainless Steel Bracket Work

- High Quality Silicon Coupler

INTAKE HOUSING ASSEMBLY

The filter housing assembly comprises of our bespoke generation 2 filter, aluminium cowl, CNC machined MAF tube and the Plastic pod itself. The pod shrouds the reverse mounted filter and smoothly shapes the airflow down to the intake tube. This smooth reduction in cross sectional area invokes the Venturi effect where the airflow accelerates whilst maintaining laminar conditions. It can be thought of as a large velocity stack - below is a diagram to show the comparison between our patented design and a regular intake system. Our bespoke filters aid the airflow moving through the housings and allow for an even velocity profile as the airflow exits the housings. Further details can be read in the Technology and Filters pages.

The MAF tube is CNC machined with tight tolerances to ensure the sensor works within the OEM parameters and therefore does not cause an engine warning code. Since the MAF tube is positioned near the exhaust manifold it is subject to high temperatures and can become heat soaked. To combat this we have insulated the tube with a neoprene rubber wrap which effectively protects the inside of the tube from high temperatures.

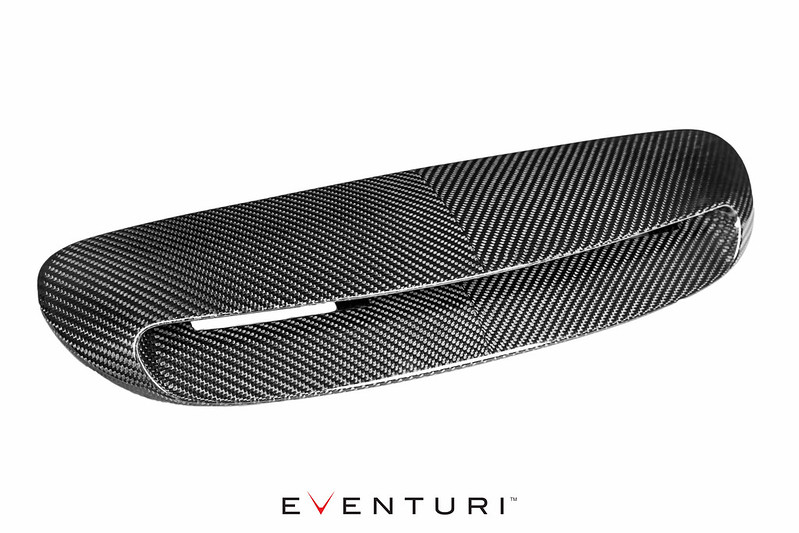

CARBON INTAKE SCOOP

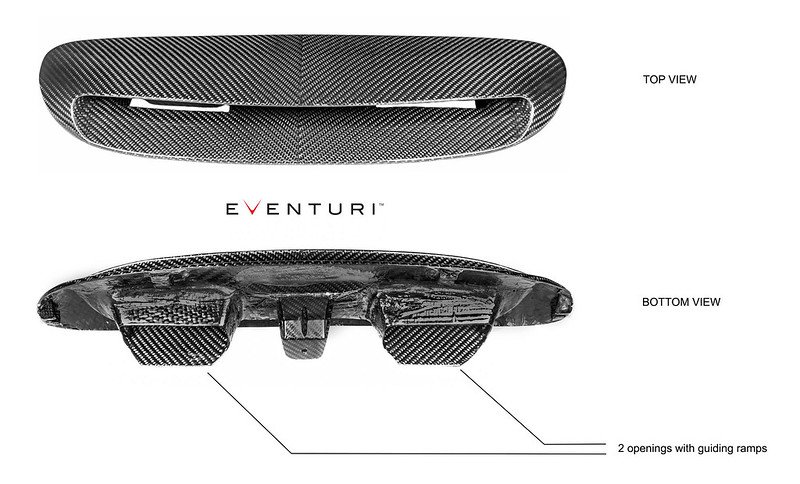

The OEM intake system draws in air from behind the front grill, above the radiator. The openings for the intake of ambient air are relatively small and therefore can lead to heat soak of the intake especially on a tuned Mini. The OEM bonnet scoop does not provide air directly to the intake and since the bonnet already has 2 cut-outs under the scoop, we decided to utilise this feature and redevelop the scoop. Our scoop is a direct replacement of the OEM part and clicks into place using the same fastening method. It features 2 inlet ramps which guide external air through the existing cut-outs on the bonnet and into the inlet duct (see below). As the car speeds up, more air is forced into the duct keeping inlet temperatures to a minimum and avoiding the heat soak issue. The scoop has a redesigned profile with a longer top surface to cover the openings which also provides a more aggressive look. Crafted from 100% prepreg carbon fibre, the scoop provides an incredible aesthetic to the vehicle. To further enhance the aesthetic feature - we used a V-shaped split weave with the carbon to give a symmetrical profile which works well as the scoop sits in the middle of the bonnet.

By making use of the existing openings in the bonnet - the ramps on the carbon scoop extend through and guide the airflow into the duct. Here is the underside of the bonnet with the scoop installed.

INLET DUCT

The OEM duct only draws air from behind the front grill and is very shallow over the slam panel. We have redesigned the duct to allow air in from the grill and also from the scoop. Furthermore, our duct has a much larger internal volume which allows the intake system to breath with less restriction. In order to protect against engine bay heat - the duct has a flexible rubber edging around the openings to the underside of the bonnet which seals to the bonnet once closed. It also has an expandable rubber edging around the opening to the filter housing which ensures a good seal to the filter as well as allowing movement with the engine.

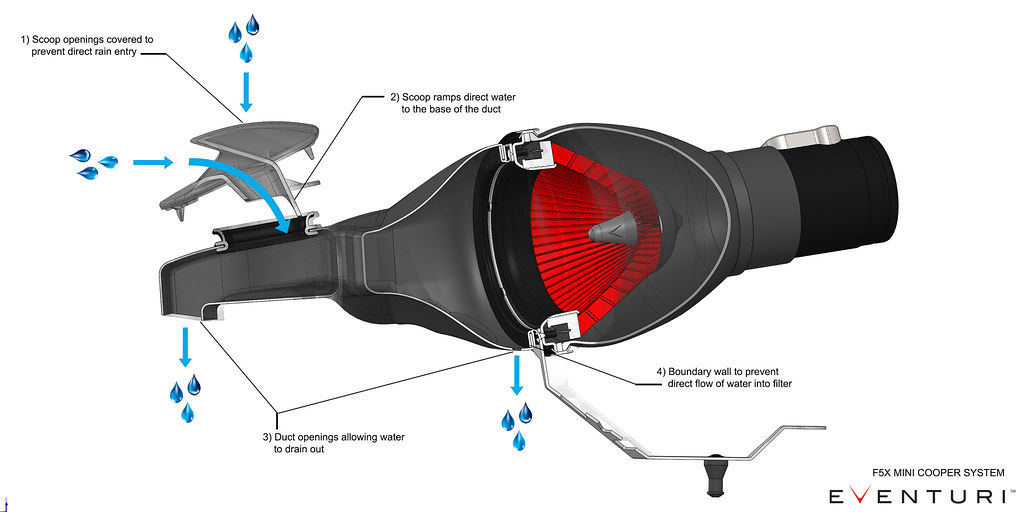

WATER DRAINAGE

Since we have a direct airflow path to the filter, it is important that we also allow for water to be drained before reaching the filter. In order to protect against excess water ingress, we have designed several features into the intake components as follows.

- 1) The top of the scoop covers the openings which stops rainfall entering the duct when the car is at a standstill.

- 2) The scoop has 2 flow directing ramps which also act as a water barrier by forcing the water to fall down onto the base of the duct rather than moving straight to the filter area.

- 3) The duct has 2 openings to allow water to drain out - above the radiator and also a drain hole before the filter housing connection.

- 4) The face of the duct as it meets the filter housing has a wall on which the rubber edging is secured. This wall stops any build up of water from directly entering the filter and water is drained through the extra drain hole.